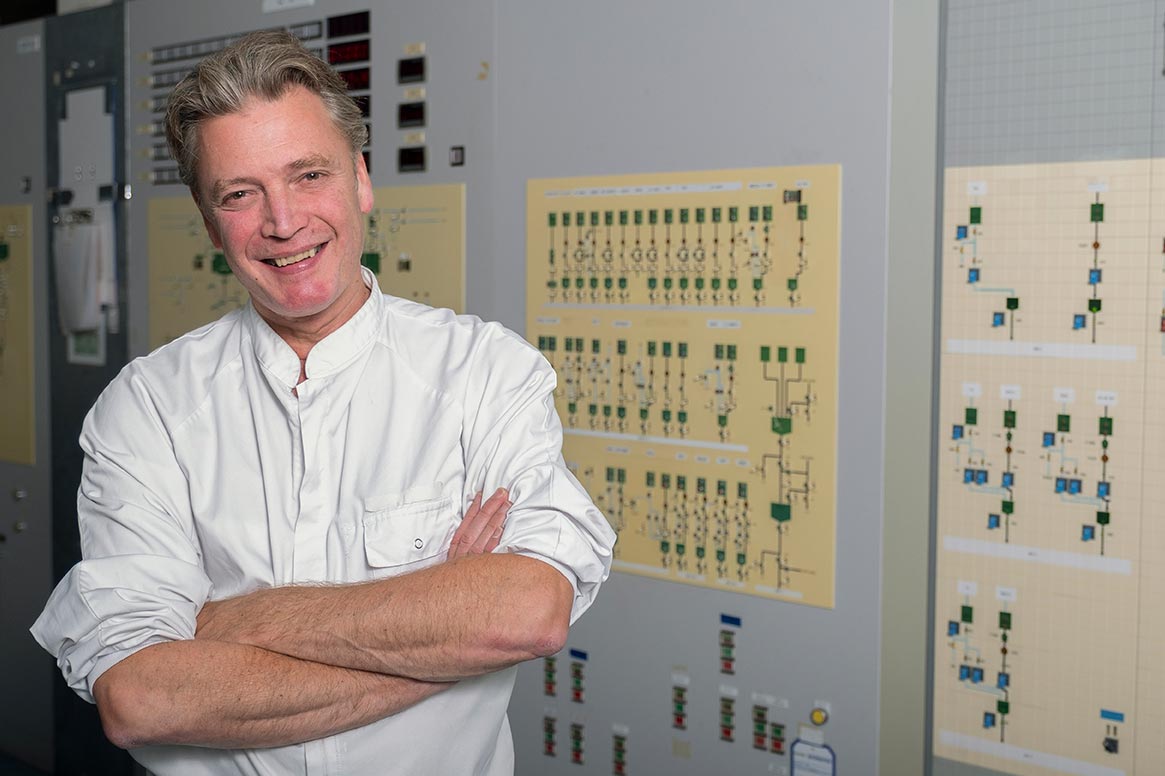

Jos Peters

A master at CLP Emulsion Manufacturing

Jos Peters, according to colleague Marc van Loon, is ‘’a source of inspiration for the emulsion process.’’ Since he started his career in 1987, Jos has become one of the company’s most experienced emulsion specialist while also expanding the application of his skills to coating and finishing plants.

Manufacturing CLP products involve three processes, and Jos has developed expertise in all of them, from producing light-sensitive and color-defining emulsions and coating them on laminated paper to slitting the coated CLP rolls to requested formats for customers. He sees his job as making products with good quality at the right time, always taking into account safety and the environment.

Effective process control, Jos confirms, is especially important for responding to possible disturbances and anticipating what is coming. That’s why he regularly meets with representatives of maintenance, logistics, prescription, and technical teams to determine priorities and come to agreement on what and when certain actions should be taken. He fully supports the vital aspect of clear reporting to create a complete overview of what happened in production for colleagues.

Jos gratefully acknowledges Fujifilm’s role in enabling him to develop and effectively apply his skills through training opportunities that have included small groups activities, management training programs, and analytical trouble shooting.

Always Ensuring Safety First

Jos finds satisfaction in having finished things properly, such as ensuring that everyone can work safely during construction, which requires continuous ‘’tasting and adjustment.’’ In fact, he constantly thinks about safety, particularly since people work with machines in chemical plants. He automatically thinks about whether things can be done more efficiently or better, often adopting a ‘’helicopter view’’ to determine what is going on in the factory in general and where adjustments have to be made.

Jos’s lead technician, James Abalain, noted: ‘’Jos always works according to applicable safety rules and solves almost all emulsion malfunctions himself.’’ Moreover, he delivers advice within a team in a pleasant way and provides sound training on emulsion to new employees. His team especially appreciates the way he can quickly switch between emulsion/process and finishing with a great sense of responsibility while remaining cheerful and driving to learn.