Labs deal responsibly with photochemistry waste

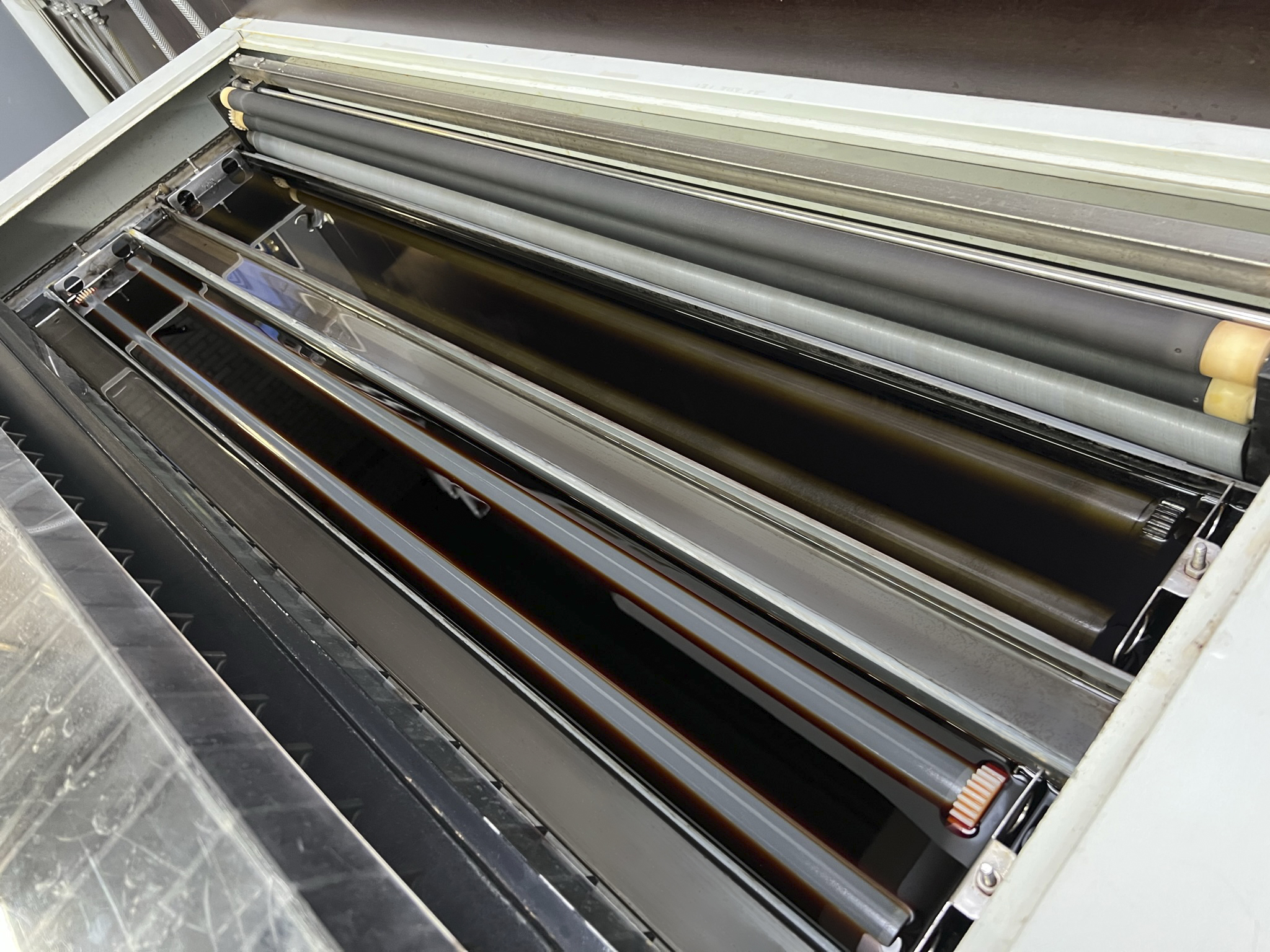

A Belgian photo lab gives us an insight into the processing of its chemicals. It shows us that, in fact, all materials from the process are recycled. But let’s start at the beginning: exposed material is developed and fixed in a developing machine with developer and bleach. The photographic residual liquids from these two types of photochemistry are pumped directly from the developing machines to large vessels specially made for the storage of liquids.

When the drums become full, they are pumped empty and taken away by a recognised collector and processor of industrial waste in Belgium specialising in recovering nickel, copper, tin and silver. This waste processor has an extensive environmental permit for the storage/transshipment and processing of hazardous and non-hazardous waste.

The different processing methods are grouped under a specific R or D code in waste processing. R stands for recovery and D for disposal. R applications therefore involve a form of recycling and D applications involve disposal (landfill, incineration or discharge). The photochemical waste from this Belgian photo lab is 100% processed through R applications only.

Photochemistry consists of ± 95% water and ± 5% photographic chemicals. In Belgium, they first separate silver from these 5% photographic chemicals. The remainder will be sent to the nationally operating EVG waste management group in Germany. They use advanced chemical-physical treatment systems and have renounced traditional combustion systems to protect the environment. By recovering secondary materials within the process, they can be fed back into the economic cycle. The residual liquid is therefore also processed via an R application.

First, the used solution is filtered to remove any remaining metal particles. Next, nitrogen is added to the last remnant of the photographic chemicals and the final new product called Kontranox is supplied to the cement industry. Here Kontranox is used in cement kilns to reduce NOx (nitrogen oxide) emissions.

So we can say that the photographic liquids released during our procedures are completely processed. There is no residual waste.